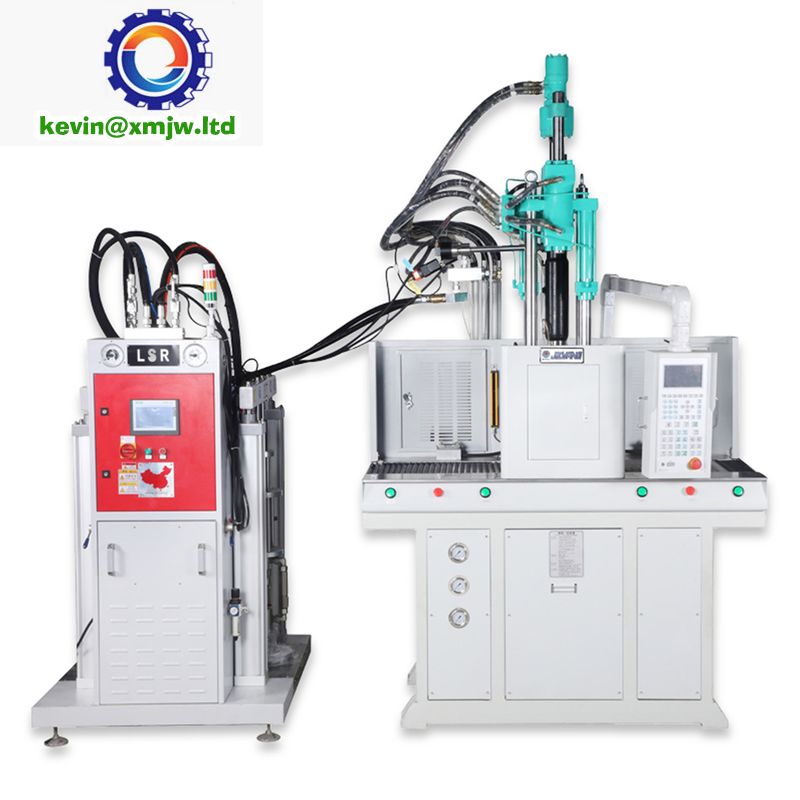

Silicone Injection Molding Machine Diving mask Swimming 160 ton injection molding machine

- Brand: JIEYANG

- Product Code: CN230813900282

- Availability: 500

High Quality Silicone Injection Molding Machine Diving mask Swimming 160 ton injection molding machine

Main Features

1.Vertical four-column direct pressure die locking,vertical injection, Chinese/ English electronic control, full screen display, proportional pressure, flow control mechanical structure optimization, smooth operation, fast speed.

2.The slide plate and the bottom plate are made of nodular castiron. The location of the steel strip is isolated. There are lubrication oil holes, which greatly reduce the wear and deformation of the slide, and increase the service life and accuracy of the slide.

3.Thimble can be used in combination with different skateboards, and the travel can be adjusted freely. Demoulding force, thimble advance and retreat speed and ejection frequency can also be preset according to need.

4.The dual mode slide plate is replaced by two modes, alternately sliding around one mold, and one die is embedded in the outside. The operation safety is high, and the productivity can be increase by 30%-50%.

5.Diversified oil system design(semi-closed, full-closed,servo or high-speed injection molding) can meet customer needs, expandable programming, and automatic embedded and removal equipment, to achieve automatic operation.

Machine Application

Vertical silicone injection machine have the advantage of low noise, low energy consumption,high efficiency and long life time, it's widely apply to produce various diving masks, headbands, breathing masks, baby pacifiers, teether mouthpieces, children's toothbrushes, surgical appliances, beauty cosmetics, sealing strip seals, wire harness seals, connector seals, etc.

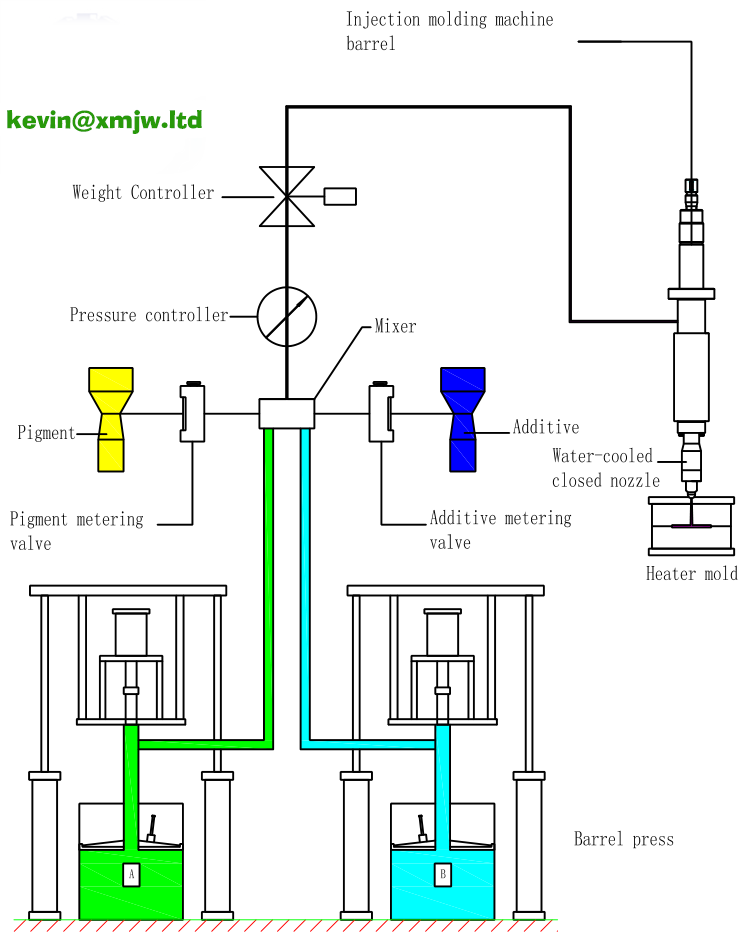

Machine working principle

Machine Main Products:

Application

Detailed Image

1.Taiwan Oil Pressure Valve. 2.Taiwan TAIHUI Solenoid Valve.

3.PORCHESON PC Control Monitor. 4.Dongguan Low Noise Injection Molding Machine Special Motor.

5.1 year warranty. 6.Specific Alloy Tube(PA66+GF).

7.Taiwan FOTEK Proximity Switch. 8.Shih Lin Contactor Control Motor

9.Japan NOK Seal. 10.Each machine packed with 1 set tool

11.Taiwan Yong Ling Pump.Da Li Hydraulic Motor.

Introduce

| After-sales Service Provided | Video technical support |

| Applicable Industries | Building Material Shops;Manufacturing Plant |

| Application | Menstrual Cup |

| Automatic | Yes |

| Brand Name | JIEYANG |

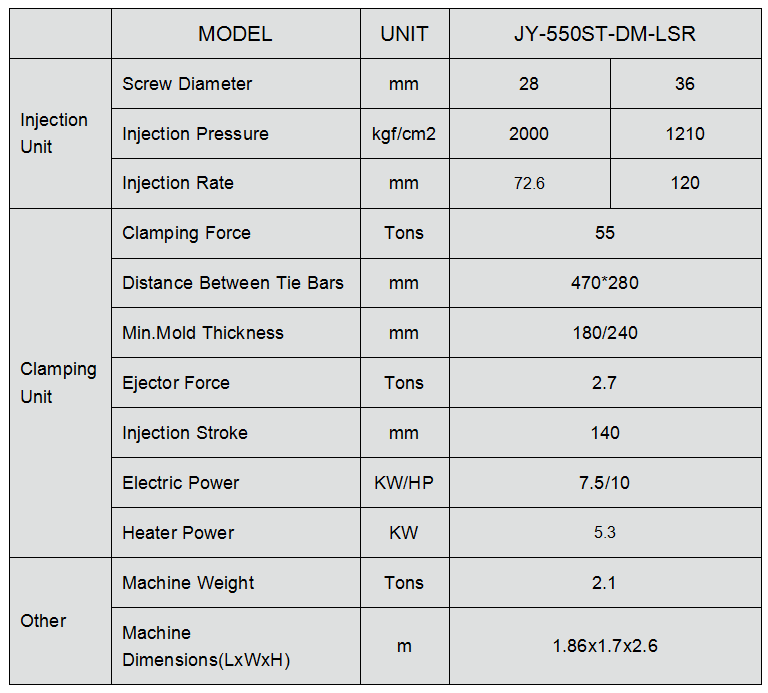

| Clamping Force (kN) | 55 tons |

| color | Blue White |

| Condition | New |

| Core Components | Bearing;Motor;Pump;Gear;Engine |

| Distance between Tie Bars | // |

| Ejector Force(kN) | 26.5 kN |

| Ejector Number | 0 |

| Ejector Stroke(mm) | 140 mm |

| Function | Silicone Parts Production |

| Injection Rate (g/s) | 120 g/s |

| Injection Weight (g) | 170.8 g |

| Key Selling Points | High Productivity |

| Machine Color | Customized |

| Machine Type | Hydraulic |

| Machinery Test Report | Not Available |

| Mold Height(mm) | 180 - 480 mm |

| Motor | Servo Energy Saving |

| Open Stroke(mm) | 180 mm |

| Place of Origin | Guangdong;China |

| Plastic Processed | silicone |

| Plastic Type | Thermoplastic |

| Power (kW) | 12.8 kW |

| Product name | silicone Injection Moulding Machine |

| Screw diameter (mm) | 36 mm |

| Screw L/D Ratio | 22 |

| Screw Speed (rpm) | 1 - 200 rpm |

| Showroom Location | Viet Nam |

| Style | VERTICAL |

| Theoretical Shot Volume(cm³) | 142.4 cm³ |

| Type | Tube Shoulder Injection |

| Video outgoing-inspection | Not Available |

| Warranty | 1 Year |

| Warranty of core components | 1 Year |

| Weight (KG) | 21000 kg |

Tags: Silicone Injection Molding Machine, Diving mask Swimming 160 ton injection molding machine